Designing and analyzing pilot operated pressure regulators requires a thorough understanding of fluid mechanics principles and control theory. These regulators utilize a small, controlled flow of fluid, known as the pilot signal, to regulate a larger main valve controlling the primary flow path. The design process typically begins with identifying the application requirements, such as pressure range, flow rate, and accuracy specifications. Next, engineers select suitable components based on these specifications, considering factors like material properties, valve characteristics, and actuation system.

- Analysis tools are then employed to forecast the regulator's performance under various operating conditions. This assessment helps in fine-tuning the design parameters to achieve the desired accuracy and stability.

- Furthermore, experimental testing is often conducted to confirm the simulation results and evaluate the regulator's real-world performance. Through this iterative cycle, engineers can develop highly effective pilot operated pressure regulators that meet the specific needs of various applications.

Attributes Characteristics of Pilot Operated Regulators

Pilot operated regulators are efficiently versatile control devices used to regulate the pressure of a fluid in various industrial and commercial systems.

Their essential function is to maintain a stable downstream pressure regardless of fluctuations in upstream conditions. This characteristic makes them appropriate for applications where precise volume control is critical.

The performance characteristics of pilot operated regulators are affected by a number of factors, including the design parameters of the regulator itself, the properties of the fluid being regulated, and the operating conditions.

These factors can affect parameters such as accuracy, reaction speed, and pressure differential.

Understanding these performance characteristics is essential for selecting the appropriate pilot operated regulator for a given application.

Meticulous consideration should be given to the required pressure control accuracy, response time, and operating range to ensure optimal efficiency.

Uses of Pilot Operated Regulators in Industrial Processes

Pilot operated regulators play a essential role in various industrial processes. They regulate the flow of gases with accurate accuracy, guaranteeing process stability.

In assembly lines, pilot operated regulators stabilize the pressure of compressed air, that is crucial for powering machinery and tools.

Furthermore, they are extensively used in pharmaceutical production to adjust the flow of reactants in processes.

For example,in a chemical plant, pilot operated regulators can be used to control the flow of reactants into a reactor, ensuring that the reaction proceeds at the desired rate and yield. In an oil refinery, they are used to regulate the pressure of crude oil as it flows through pipelines and processing units.

This accurate regulation is vital for improving product quality and more info safety.

Addressing Common Issues with Pilot Operated Regulators

Pilot operated regulators are vital components in many pneumatic systems, ensuring precise pressure control. However, like any mechanical device, they can experience problems. A common fault is a volume drop, which can be caused by several factors such as a blocked pilot line, a faulty diaphragm, or wear to the regulator valve. To troubleshoot these issues, it's important to meticulously inspect the regulator and its related components.

Start by checking the pilot air supply pressure using a pressure gauge. If the pressure is low, the issue could be in the upstream circuit.

Next, examine the pilot line for any blockages.

Similarly, it's important to ensure that the diaphragm and valve are not defective. If you suspect a issue with the diaphragm, replace it with a new one.

Finally, always turn to the manufacturer's recommendations for specific maintenance procedures.

Factors for Selecting Pilot Operated Regulators

When selecting pilot operated regulators, several key factors must be thoroughly considered to ensure optimal operability. Fundamental considerations include the specific industry requirements, such as pressure range, flow rate, and media compatibility.

- Moreover, the regulator's actuation speed should be aligned to the demands of the process.

- Robustness is crucial, particularly in harsh operating environments.

- Lastly, maintenance requirements and the readiness of spare parts need to be assessed

By carefully assessing these parameters, engineers can choose the most effective pilot operated regulator for their unique needs.

Manage Strategies for Pilot Operated Regulators

Pilot operated regulators implement a diverse range of control strategies to precisely regulate pressure. These strategies often involve feedback loops, pneumatic components, and complex algorithms to ensure stable and reliable operation.

Common control techniques for pilot operated regulators feature:

- {Proportional-Integral-Derivative (PID) control: This widely used strategy adjusts the regulator output based on the deviation between the setpoint and the actual process variable, utilizing proportional, integral, and derivative terms to achieve optimal performance.

- {Cascade Control: This technique employs two or more regulators operating in a sequential arrangement. The outer loop regulates the primary variable, while the inner loop refines a secondary variable that directly influences the primary variable.

- {On-Off Control: This simple strategy switches the regulator output between fully open and fully closed states based on whether the process variable exceeds a predetermined setpoint.

The selection of the most appropriate control method depends on the specific application requirements, including system complexity. Careful tuning of these strategies is crucial for achieving stable and efficient operation of pilot operated regulators.

Alicia Silverstone Then & Now!

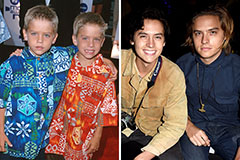

Alicia Silverstone Then & Now! Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Andrew McCarthy Then & Now!

Andrew McCarthy Then & Now! Jeri Ryan Then & Now!

Jeri Ryan Then & Now! Peter Billingsley Then & Now!

Peter Billingsley Then & Now!